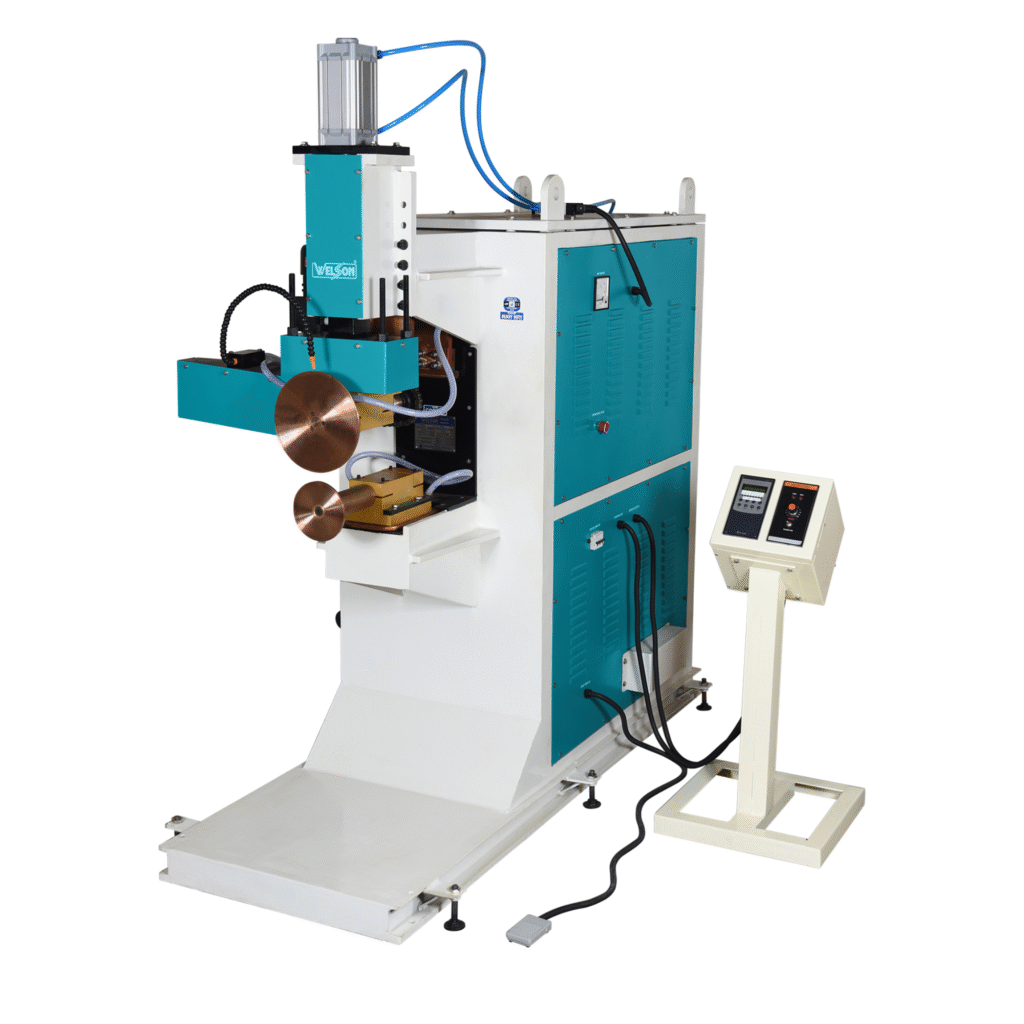

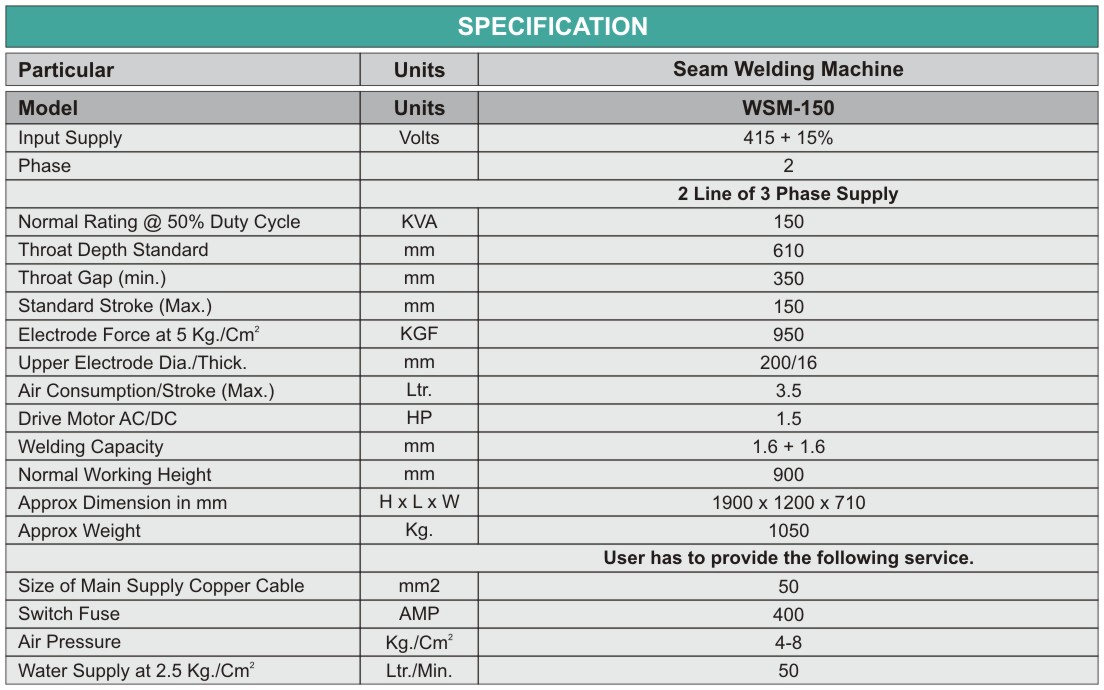

SEAM WELDING MACHINE WSM-150

Scope & Applications

“WELSON” SEAM WELDING Machine are

offered in 150 and more KVA models. Seam welding is a resistance welding technique where two overlapping metal sheets are joined along a continuous seam. It uses rotating wheel-shaped electrodes (typically copper-alloy) that apply pressure and pass electric current through the workpieces, generating heat due to electrical resistance. This heat melts the metal at the contact points, forming a leak-proof, continuous weld.

TRANSFORMER :

Low leakage [High linkage] design, proper cooling and insulation including winding impregnation to enhance reliability and service life.

TIME CURRENT CONTROL:

Current setting from min. to max.

can be done. Speed drive can be controlled from high to low depending on your

work.